In most industries, technology either changes the product or the process. DreamSofa decided to change both.

The Los Angeles–based custom furniture maker recently unveiled its DreamModular™ Collection, backed by an $8 million investment in advanced U.S. factory robotics. The goal: deliver sofas designed down to the inch – and deliver them in record time – without sacrificing craftsmanship.

Robotics Meets Handcrafted Quality

DreamSofa’s new manufacturing system uses precision robotics to cut, join, and finish kiln-dried hardwood frames with near-zero margin for error. This automation speeds up the build process while improving consistency, allowing the brand to ship custom orders in as little as three weeks.

But the human touch isn’t gone. Skilled upholsterers, fabric specialists, and quality-control teams still handle the detail work – from perfectly aligning tufting to applying PFAS-free, spill-resistant finishes. It’s a human–machine partnership aimed at raising the bar for made-to-order furniture.

A Digital-First Buying Experience

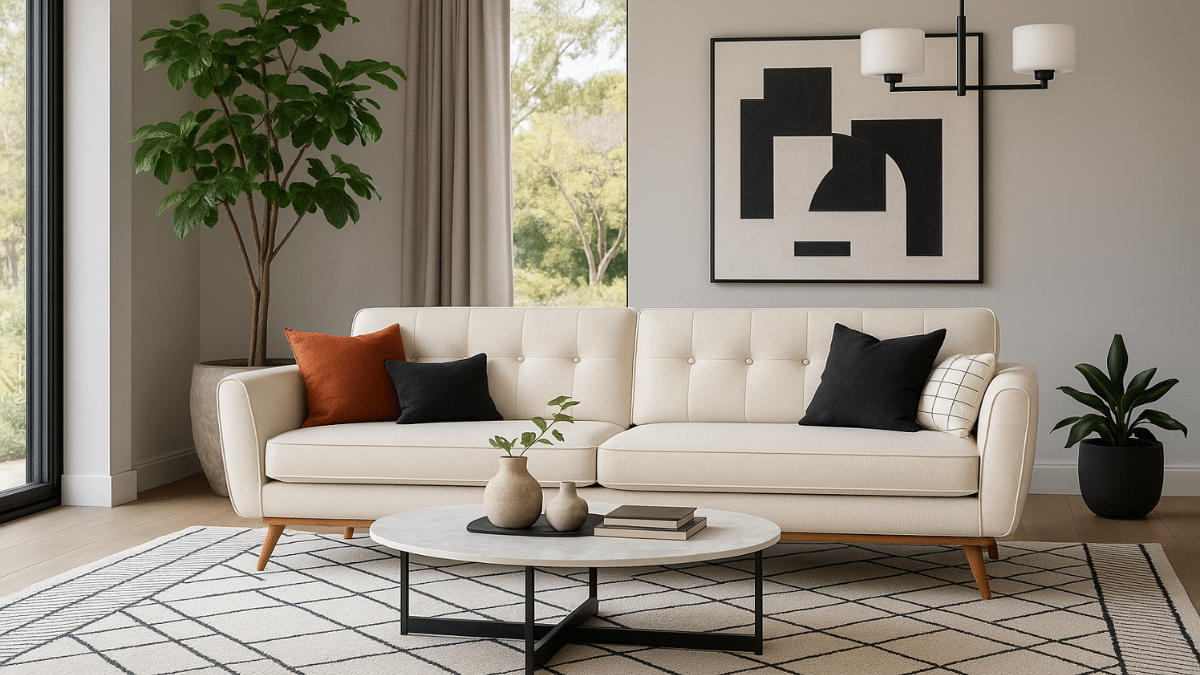

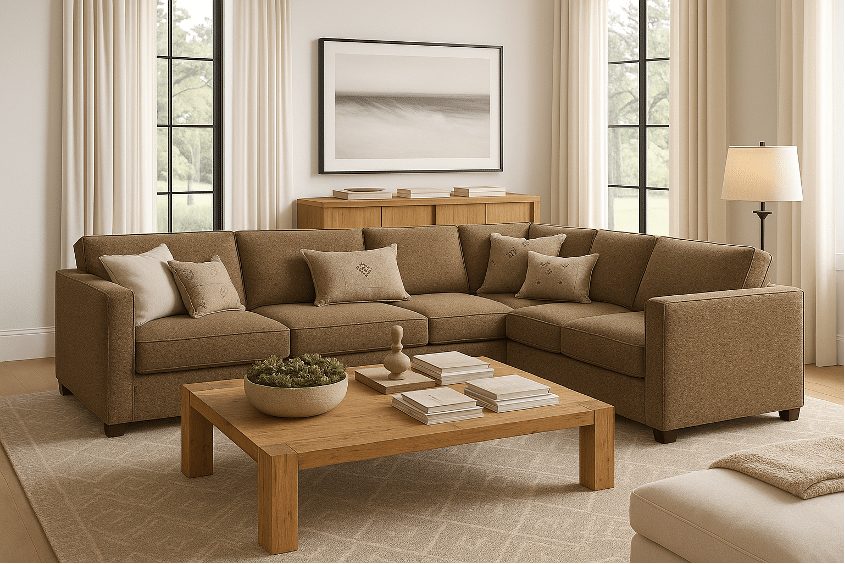

Tech doesn’t stop at the factory floor. DreamSofa’s DreamVision™ 3D Configurator and AR Studio let customers visualize their sofa in real time, experimenting with layouts, fabrics, and finishes before placing an order. Modules can be reconfigured post-purchase in under five minutes thanks to tool-free steel-lock connectors, so the same sofa can evolve with your space.

This combination of interactive design and rapid, flexible manufacturing mirrors the mass personalization trend in industries like sneakers, eyewear, and even electric cars – but with the logistical complexity of large-scale furniture.

Smart Features for Connected Living

Select DreamModular™ arm modules include integrated USB-C ports and wireless charging pads, so you can power devices without extra clutter. And because all finishes are zero-VOC and non-toxic, the tech-forward experience doesn’t come at the expense of indoor air quality.

Why It Matters in the Bigger Tech Picture

Furniture is one of the slowest-moving consumer goods categories when it comes to integrating advanced manufacturing. By combining robotics, AR design tools, and modular engineering, DreamSofa is showing how traditionally slow, high-touch industries can compete on speed, personalization, and sustainability – all at once.

For customers, that means a sofa tailored to your exact specifications, built in the U.S., delivered in weeks, and ready to adapt to your life for years to come.

Explore the DreamModular™ Collection

Frequently Asked Questions

1. What makes DreamSofa’s $8M robotics investment significant?

It allows DreamSofa to maintain handcrafted quality while dramatically improving production speed and consistency, cutting lead times to just 21–35 days for fully custom builds.

2. How does the DreamVision™ 3D Configurator work?

It’s an interactive design tool that lets you preview your custom sofa in real time, adjusting dimensions, fabrics, arm styles, and configurations before you place your order.

3. Can DreamModular™ sofas really be reconfigured without tools?

Yes. Each module connects with heavy-duty steel-lock connectors that can be secured or released in under five minutes, making layout changes quick and easy.

4. Are there built-in smart features?

Select arm modules come with USB-C charging ports and wireless charging pads, designed to keep devices powered without extra cables or adapters cluttering your living space.

5. Is the DreamModular™ Collection eco-friendly?

Yes. All finishes are zero-VOC, fabrics are PFAS-free, and the modular design encourages long-term use by allowing parts to be updated or replaced instead of replacing the entire sofa.